A sharp knife ensures kitchen safety. It also improves efficiency during food preparation. A dull blade compromises the cooking experience. It makes food preparation difficult and less enjoyable. Selecting the correct Knife Sharpener significantly enhances culinary tasks. A 3-Stage Knife Sharpener or even a 4-Stage Knife Sharpener can restore edges, making cooking more precise.

Key Takeaways

- A sharp knife makes cooking safer and easier.

- Different knives need different sharpeners; match the sharpener to your knife’s material and edge type.

- Choose a sharpener that fits your skill level, from easy-to-use models for beginners to advanced tools for experts.

- Decide how sharp you want your knife; some sharpeners are for quick touch-ups, others for a very sharp edge.

- Think about how much time you want to spend sharpening; some methods are fast, others take more time.

- Consider your budget; sharpeners range from cheap to very expensive.

- Look for sharpeners with good safety features like non-slip bases and finger guards.

- A good sharpener can also sharpen other tools like scissors or outdoor knives.

Understanding Different Knife Sharpener Types

Many different types of knife sharpeners exist on the market. These include benchtop, field, and kitchen sharpeners. Each type offers unique benefits and caters to different sharpening needs. A common type, for instance, is a Manual 3 Stage Kitchen Knife Sharpener with a Non-Slip Handle. This design prioritizes high quality, durability, and effectively restores and polishes blades. Understanding these various options helps individuals choose the best tool for their specific knives.

Manual Pull-Through Knife Sharpeners

Manual pull-through sharpeners offer a straightforward approach to blade maintenance. They are small, portable, and easy to use, making them popular for quick touch-ups. Users simply pull the knife through designated slots. This method quickly smooths out small nicks and reintroduces an edge bevel. These sharpeners are often inexpensive and require minimal skill. However, the resulting edge can be rough. Some versions, particularly those with tungsten carbide, remove too much blade material. This can shorten a blade’s lifespan. Fixed sharpening angles may also not suit all knife types.

Ceramic Rods for Fine Edges

Ceramic rods within pull-through sharpeners provide a finer grit. They are ideal for refining an edge after initial sharpening. These rods help achieve a smoother, more polished finish. They gently hone the blade, preparing it for precision tasks.

Carbide Blades for Coarse Sharpening

Carbide blades offer aggressive material removal. They quickly restore a very dull or damaged edge. These blades are effective for coarse sharpening, setting the initial angle, or fixing heavily rolled edges. They efficiently remove metal to reshape the blade.

Electric Knife Sharpeners

Electric knife sharpeners provide a fast and simple way to sharpen knives evenly. They require minimal effort from the user. Individuals plug them in, turn them on, and draw the blade through the slot. This method significantly reduces the skill requirement compared to manual sharpening. Electric sharpeners often feature multiple slots with specific functions. They also include spring-loaded blade guides to maintain the correct angle. This makes improper use nearly impossible. Many models offer versatility, with options for sharpening, stropping, and polishing. They can recondition very dull blades using hardened steel wheels. However, quality electric sharpeners can be expensive, ranging from $90 to $180. Improper use can also damage a knife, and some models occupy significant kitchen counter space.

Multi-Stage Systems for Comprehensive Sharpening

Multi-stage electric sharpeners offer a comprehensive sharpening process. They typically feature different slots for coarse, medium, and fine grinding. This system allows for full blade restoration, from repairing damaged edges to achieving a razor-sharp finish.

Single-Stage Options for Quick Touch-Ups

Single-stage electric sharpeners provide a quick solution for maintaining an already decent edge. They are ideal for fast touch-ups between uses. These options offer convenience and speed for everyday kitchen tasks.

Sharpening Stones (Whetstones)

Sharpening stones, also known as whetstones, represent a traditional and highly effective method for sharpening knives. They come in various materials, each suited for different sharpening stages and blade types. Users apply water or oil as a lubricant, depending on the stone.

Water Stones for Precision Sharpening

Water stones are softer than oil stones. They release abrasive particles during sharpening, which creates a fresh cutting surface. These stones excel at producing fine edges and polishing blades. They require soaking before use and regular flattening to maintain their effectiveness.

Oil Stones for Durability

Oil stones, made from materials like Novaculite or aluminum oxide, are harder and more durable than water stones. They are less messy and suitable for general sharpening and edge maintenance. Oil prevents metal particles from clogging their pores.

Diamond Stones for Harder Steels

Diamond stones are extremely hard and durable. They can sharpen any material, including ceramics and carbide. These stones are available in various grits, from coarse to extra-fine. They do not dish or wear out, making them a long-lasting option for harder steels.

Honing Rods (Steels) for Knife Maintenance

Honing rods, often called steels, serve a crucial role in knife maintenance. They differ significantly from sharpeners. A honing rod’s primary function is to realign a slightly misaligned edge. It does this without removing significant blade material. This process keeps the knife cutting cleanly and smoothly. It is a maintenance step, not a sharpening step that creates a new edge. Honing a knife primarily corrects a misaligned edge. It ensures the edge remains straight and not bent. Regular use, such as during meal preparation, often causes a knife’s cutting edge to fold over. Honing rods address this common issue.

Steel Rods for Realignment

Traditional steel honing rods are common in many kitchens. They feature fine ridges along their surface. These ridges gently push the microscopic edge of a blade back into alignment. Users hold the rod vertically and draw the knife blade down and across it at a consistent angle. This action straightens the edge. Steel rods are effective for daily maintenance. They help maintain a knife’s sharpness between full sharpening sessions.

Ceramic Rods for Gentle Honing

Ceramic honing rods offer a finer abrasive surface than steel rods. They provide a gentler honing action. These rods not only realign the edge but also perform a very light abrasive action. This action refines the edge slightly. Ceramic rods are excellent for maintaining a keen edge on knives that are already sharp. They are also useful for removing minor burrs. Their fine grit helps achieve a smoother finish.

Diamond Rods for Light Sharpening

Diamond honing rods feature industrial diamonds bonded to their surface. These rods are more abrasive than both steel and ceramic options. They can perform light sharpening in addition to honing. Diamond rods effectively realign the edge and remove a small amount of metal. This makes them suitable for knives that have become slightly dull but do not require a full sharpening. They work well on harder steel blades.

Belt Knife Sharpeners

Belt knife sharpeners utilize abrasive belts to sharpen blades. These machines offer versatility and efficiency. They can handle various blade types and achieve different levels of sharpness. Belt sharpeners are popular among enthusiasts and professionals. They provide precise control over the sharpening angle and pressure. This allows for consistent and high-quality results.

Grinding Belts for Aggressive Material Removal

Grinding belts come in coarser grits. They are designed for aggressive material removal. These belts quickly reshape a blade or repair significant damage. They can restore a completely dull or chipped edge. Users can set the desired angle and pass the blade across the moving belt. This process efficiently removes metal. It establishes a new, sharp edge.

Polishing Belts for Refined Edges

Polishing belts feature very fine grits. They are used after coarser grinding belts. These belts refine the edge to a razor-sharp finish. They remove any remaining burrs and polish the blade surface. This results in an exceptionally smooth and keen edge. Polishing belts contribute to the ultimate sharpness and cutting performance of a knife.

Factor 1: Your Knife Collection and Blade Types

Selecting the right Knife Sharpener begins with understanding your existing knife collection. Different knives feature distinct materials and edge types. These characteristics directly influence the most effective sharpening method. A sharpener suitable for one blade may not perform well on another. Therefore, evaluating your knives’ composition and design is a crucial first step.

Knife Material Considerations for Your Knife Sharpener

Knife materials vary widely. Each material possesses unique hardness and durability. These properties dictate the type of abrasive needed for effective sharpening.

Stainless Steel Knives Compatibility

Stainless steel knives are common in most kitchens. They offer good corrosion resistance and reasonable edge retention. Most standard sharpeners, including manual pull-through and electric models, work well with stainless steel. These knives generally do not require highly specialized abrasives.

High-Carbon Steel Knives Requirements

High-carbon steel knives hold a very sharp edge. They are also more prone to rust. Sharpening high-carbon steel requires careful attention to grit selection.

- For tougher knife materials, a 1000 grit whetstone is advised for an improved sharpening experience.

- Selecting the appropriate medium grit stone, specifically between #800 and #2000, is crucial for effective sharpening based on the knife’s material.

- A 1000 grit stone is generally versatile for most knives, though it may not be ideal for extremely hard steel.

These knives benefit from sharpeners that allow precise control over the sharpening angle and grit.

Ceramic Knives Specific Sharpeners

Ceramic knives are extremely hard. They maintain their edge for extended periods. However, they are also brittle. Standard sharpeners cannot effectively sharpen ceramic blades. These knives require diamond abrasives. Diamond stones or specialized electric sharpeners designed for ceramic are necessary.

Blade Edge Type and Your Knife Sharpener

The shape of a knife’s edge also dictates the appropriate sharpening tool. Different edge profiles demand different approaches.

Straight Edge Knives Sharpening

Straight edge knives are the most common type. They feature a continuous, un-serrated cutting surface. These knives are generally easy to maintain. Most sharpeners, including pull-through, electric, and whetstones, can sharpen straight edges effectively. They are ideal for precision cutting tasks.

Serrated Edge Knives Solutions

Serrated knives have a series of teeth along the blade. They excel at cutting through tough exteriors. Sharpening serrated edges requires specialized tools. Standard sharpeners often damage serrations.

| Blade Type | Sharpening Requirement |

|---|---|

| Plain Edge | Easy to maintain, ideal for precision cutting |

| Serrated Edge | Requires specialized sharpening |

| Combo Edge | Demands more effort to maintain both plain and serrated sections |

Understanding the various types of knife edges, such as V-edge, Hollow edge, Serrated edge, and Chisel edge, is crucial for selecting the appropriate sharpening method. Each edge type may require a distinct approach to maintain its effectiveness. For instance, electric sharpeners, while convenient, may not be suitable for all knife types, especially those with specialized edges. They can remove more material than necessary or fail to achieve the desired sharpness compared to traditional methods.

Asian-Style Knives Angle Needs

Asian-style knives, like Santokus and Nakiris, often feature a thinner blade and a steeper sharpening angle. This angle is typically between 10 and 15 degrees per side. Many Western knives have a 20-degree angle. Sharpeners with adjustable angles or those specifically designed for Asian knives are best. This ensures the correct edge geometry.

Factor 2: Your Sharpening Skill Level with a Knife Sharpener

Your personal sharpening skill level significantly influences the best choice for a sharpening tool. Beginners benefit from simpler systems. Experienced users often prefer tools offering greater control and precision. Matching the tool to your expertise ensures effective sharpening and avoids frustration.

Beginner-Friendly Knife Sharpener Options

Beginners need tools that simplify the sharpening process. These options minimize the learning curve. They help users achieve decent results quickly.

Guided Systems for Consistent Angles

Guided systems provide excellent support for new sharpeners. They ensure consistent angles, which is crucial for effective sharpening. The Work Sharp Professional Precision Adjust Elite offers adjustable angle settings and multiple grit plates. This system delivers consistent results, though it has a learning curve and higher price.

Fixed-Angle Sharpeners for Ease of Use

Fixed-angle sharpeners are very user-friendly. Manual pull-through sharpeners, like the Kitchellence 4-in-1, are easy to start with. They often feature preset angle guides. Electric sharpeners also offer convenience and speed with minimal effort. The Chef’sChoice 1520 AngleSelect is recommended for its preset angle guides and tactile feedback. However, users should exercise caution to avoid removing too much metal.

Intermediate Skill Knife Sharpeners

Intermediate users possess some sharpening experience. They are willing to invest time in developing greater expertise. These individuals often own a variety of Japanese, Western-style, and other knives. They seek tools offering more versatility and precise results. Mid-range knife sharpening kits, typically costing $50-$100, are ideal. The Work Sharp Precision Adjust Knife Sharpener, for example, features customizable sharpening angles and a thoughtful design. These tools provide a broad grit progression. They handle various blade conditions, from bluntness to minor chips, and maintain razor sharpness.

Manual Pull-Through Systems for More Control

Some manual pull-through systems offer more control than basic models. They allow users to refine their technique. This helps them achieve better edges.

Basic Whetstones for Developing Technique

Whetstones provide the best sharpening quality and control. They are ideal for those willing to learn. The SHAPTON Ha No Kuromaku Ceramic Whetstone Set is highly recommended for beginners ready to invest time. Intermediate users can further develop their technique with these stones.

Advanced User Knife Sharpener Tools

Advanced users demand precision and professional results. They often have a large collection of knives. They want to customize sharpening angles. These users seek top-tier performance for high-end kitchen knives.

Freehand Whetstones for Mastery

Freehand whetstones represent the pinnacle of sharpening skill. They require significant practice and mastery. Users achieve highly customized and precise edges with these tools.

Belt Sharpeners for Professional Results

Belt sharpeners deliver exceptional results for advanced and rigorous work. The Work Sharp Ken Onion Edition Elite Mk.2, for instance, features a blade grinder. Once mastered, it delivers exceptional results. It can be fastened to a workbench for more intensive tasks. Other advanced systems include the TSPROF K03 Pro AL Hunter Sharpening Kit. This system allows for accurate edges on expensive blades. It features a user-friendly digital angle gauge. It also supports aftermarket stones. The Work Sharp Professional Precision Adjust Knife Sharpener is also highly rated. It offers no guesswork with edge angles. It handles any steel and nearly any knife size. It uses highest-grade diamond stones. The HORL 2 Pro with Premium Set is recommended for premium chef knives. It delivers the best results possible among rolling sharpeners.

Factor 3: Desired Sharpness Level from Your Knife Sharpener

The desired sharpness level significantly influences the choice of a Knife Sharpener. Different culinary tasks require varying degrees of edge keenness. Understanding these needs helps select the most appropriate sharpening method.

Everyday Kitchen Sharpness with a Knife Sharpener

Achieving everyday kitchen sharpness focuses on maintaining functional edges for routine tasks. This level of sharpness ensures safe and efficient food preparation without requiring extreme precision.

Quick Touch-Ups for Regular Use

Regular use dulls knife edges over time. Quick touch-ups help maintain an acceptable level of sharpness. Several tools facilitate this process:

- Knife Sharpening Steel: This tool primarily hones rather than sharpens. It straightens the blade’s edge. Users can employ vertical or horizontal techniques. It is ideal for maintaining already sharp knives.

- Electric Knife Sharpener: This convenient option features motorized abrasive wheels. Users pull the blade through slots, alternating sides. Following manufacturer instructions is crucial.

- Manual Knife Sharpener: Similar to electric sharpeners, this tool uses abrasive surfaces in a V-shaped chamber. Users pull the knife through with even pressure.

- Whetstone (Sharpening Stone): This rectangular block often has coarse and fine sides. It requires soaking in water. Users hold the knife at a 20-degree angle and move it in a circular motion across the stone.

Basic Edge Restoration for Dull Blades

When a blade becomes noticeably dull, it requires more than a quick touch-up. Basic edge restoration aims to bring the edge back to a functional state. This often involves using coarser grits to remove more material and re-establish the primary bevel.

Razor-Sharp Edge with a Knife Sharpener

Achieving a razor-sharp edge demands meticulous technique and patience. This level of sharpness is often sought by culinary enthusiasts and professionals for precision cutting.

Fine Grit Sharpening for Precision

Fine grit sharpening refines the edge after initial coarse sharpening. This step removes microscopic burrs and polishes the blade. It prepares the knife for ultimate sharpness.

Stropping Techniques for Ultimate Sharpness

Stropping is the final step for achieving ultimate sharpness. It hones and aligns the edge. This process often uses a leather strop, with or without abrasives. Materials like cardboard, newspaper, or blue jeans can also serve as strops. Success in sharpening is approximately 80% technique and only 20% tools.

Achieving razor-sharp blades requires both proper technique and patience. When stropping, users draw the knife backward across the leather strop, alternating sides. Maintaining an angle similar to the sharpening angle is crucial. A slightly shallow angle will not contact the edge. An excessively steep angle will dull it. Leather strops are forgiving, allowing some angle variation. Users apply lighter pressure as they progress for a finer edge. To rejuvenate a dry strop, apply petroleum jelly and rub in compound.

A razor-sharp edge should effortlessly push-cut through paper with minimal force. A BESS tester measures the downward force required to cut a standard filament. This provides a quantitative numeric value for sharpness.

Factor 4: Time Commitment for Knife Sharpening

The amount of time individuals dedicate to knife maintenance varies significantly. Some prefer quick solutions. Others embrace a more deliberate, time-consuming approach. The choice of sharpening method directly impacts the time commitment. Users should consider their available time and patience when selecting a Knife Sharpener.

Quick Knife Sharpening Solutions

Many users prioritize speed and convenience. They seek methods that restore an edge efficiently. These solutions minimize the time spent on sharpening tasks.

Electric Sharpeners for Speed

Electric sharpeners offer a rapid way to sharpen knives. They feature motorized abrasive wheels. Users simply guide the blade through designated slots. This process quickly re-establish a sharp edge. Electric models significantly reduce manual effort and time. They are ideal for busy kitchens or individuals who prefer minimal fuss.

Pull-Through Sharpeners for Convenience

Pull-through sharpeners provide another convenient option for quick edge restoration. These compact tools are easy to access and use. Users draw the knife blade through abrasive slots a few times. This action quickly hones or sharpens the edge. Pull-through sharpeners are excellent for routine touch-ups. They maintain sharpness between more intensive sharpening sessions.

Time-Intensive Knife Sharpening Methods

Some sharpening techniques demand a greater investment of time and effort. These methods often yield superior results. They appeal to those who value precision and a highly refined edge.

Whetstone Sharpening for Deliberate Practice

Whetstones require a significant time commitment. Users manually glide the knife blade across the stone’s surface. This process demands focus and consistent technique. Whetstones can take up to ten times longer to sharpen a knife compared to other techniques. This deliberate practice allows for precise control over the edge angle and finish. It results in an exceptionally sharp and durable blade.

Learning Curve Investment for Long-Term Skill

Manual sharpening systems, including whetstones, involve a learning curve. Users invest time in developing proper technique. This initial investment pays off with long-term skill development. Manual sharpeners typically require two to three times more time per knife than automated methods. However, mastering these techniques provides the ability to achieve custom edges. It also extends the life of valuable knives. This approach suits individuals who enjoy the craft of sharpening.

Factor 5: Budget Considerations for a Knife Sharpener

Budget plays a significant role when individuals choose a Knife Sharpener. Prices vary widely, from inexpensive manual tools to sophisticated professional systems. Understanding these different price points helps users make an informed decision based on their needs and financial comfort.

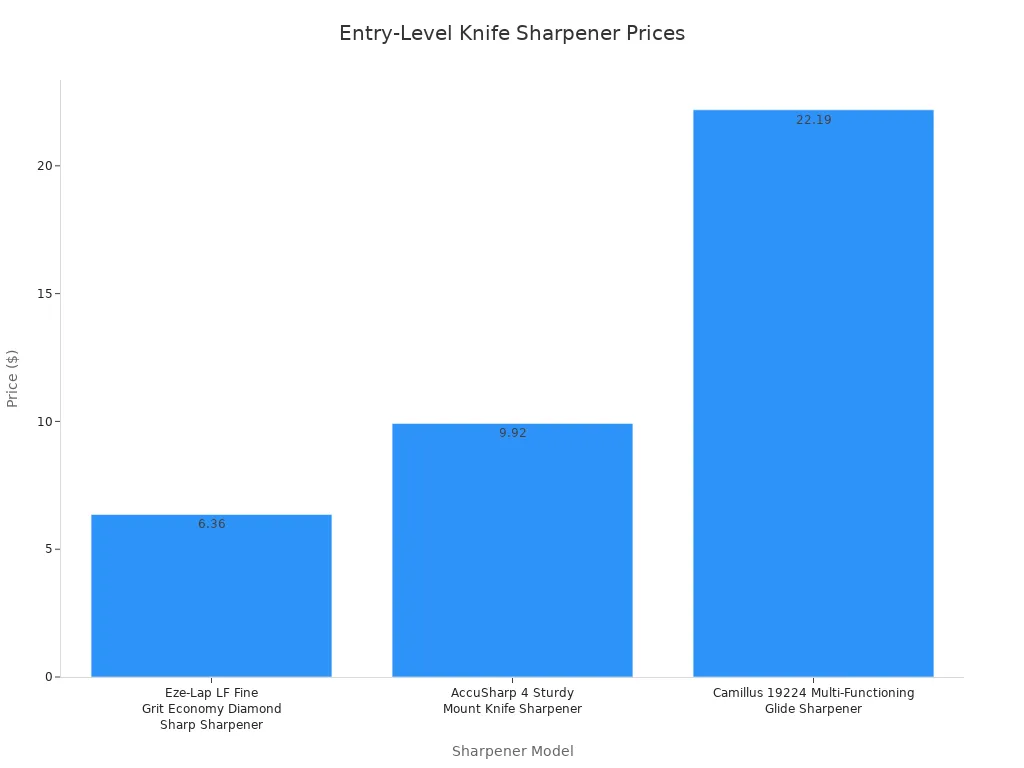

Entry-Level Knife Sharpeners

Entry-level sharpeners offer accessible options for basic knife maintenance. They typically cost less, making them suitable for those new to sharpening or with limited budgets.

Affordable Manual Options

Many affordable manual sharpeners provide quick and easy solutions. These tools often feature simple designs for straightforward use. They effectively restore a basic edge for everyday kitchen tasks.

| Sharpener Model | Price |

|---|---|

| Eze-Lap LF Fine Grit Economy Diamond Sharp | $6.36 |

| AccuSharp 4 Sturdy Mount Knife Sharpener | $9.92 |

| Camillus 19224 Multi-Functioning Glide Sharpener | $22.19 |

These examples illustrate the low cost of many entry-level options.

Basic Honing Rods for Maintenance

Basic honing rods are also very affordable. They help maintain an edge between sharpening sessions. These rods realign the blade’s microscopic edge, extending its sharpness.

Mid-Range Knife Sharpeners

Mid-range sharpeners strike a balance between cost and performance. They offer more features and better results than entry-level models without the premium price tag.

Quality Pull-Through Systems

Quality pull-through systems in this category provide improved abrasive materials and more consistent angles. They offer increased durability and better edge refinement.

Decent Electric Models for Value

Mid-range electric sharpeners deliver good value. They offer convenience and speed. These models often include multiple stages for comprehensive sharpening. They provide reliable performance for most home cooks. Mid-range sharpeners offer:

- More advanced tools and systems designed for precise results.

- Increased versatility compared to lower-priced options.

- Customizable sharpening angles (e.g., 15° to 30°).

- Secure knife clamps, often with rubber padding to prevent scratches.

- Multi-grit sharpening rods (e.g., coarse diamond, medium diamond, fine ceramic).

- Portability and compact designs for on-the-go sharpening.

- Multiple grit levels (e.g., from coarse to extra-extra fine).

- Angle adjustability for consistent edges.

- Traditional water stones with different grits for repair, sharpening, and finishing.

Premium Knife Sharpening Systems

Premium sharpening systems represent a significant investment. They deliver professional-grade results and exceptional precision. These systems cater to serious enthusiasts and culinary professionals.

High-End Whetstones for Superior Results

High-end whetstones offer superior abrasive quality. They produce incredibly sharp and polished edges. Users achieve precise control over the sharpening process with these stones.

Professional Electric Sharpeners for Durability

Professional electric sharpeners are built for durability and consistent performance. They feature robust motors and advanced abrasive technologies. These systems handle frequent use and a wide range of blade types. Premium systems include:

- TS Prof Sharpening Systems: These systems feature precision engineering, ensuring consistent edges. They offer high adjustability for various knives and tasks. They boast solid, premium construction designed for long-term use.

- Wicked Edge Precision Sharpener: This sharpener achieves perfect angles across the blade consistently. It features dual-sided sharpening, eliminating the need to flip the blade. It provides a wide array of stones and stropping options.

- Tormek T-8 Water-Cooled Sharpening System: This system delivers professional-grade results. It incorporates water cooling to prevent any damage to the blade during sharpening. It is versatile, capable of sharpening knives, chisels, axes, and more.

Factor 6: Maintenance and Durability of Your Knife Sharpener

Individuals invest in a Knife Sharpener expecting it to perform reliably over time. Therefore, evaluating a sharpener’s maintenance requirements and overall durability is crucial. These aspects directly impact the tool’s long-term effectiveness and value.

Knife Sharpener Longevity

A sharpener’s lifespan varies significantly based on several factors. Understanding these elements helps users select a durable product.

Material Quality for Extended Use

The quality of materials directly influences a sharpener’s longevity. Sharpeners crafted from high-quality materials, such as diamond or ceramic, maintain their effectiveness for extended periods. These robust materials resist wear and tear, ensuring consistent performance over many sharpening sessions. Conversely, sharpeners made from lower-quality materials tend to wear out faster. They lose their abrasive properties more quickly, necessitating earlier replacement. The frequency of use also plays a significant role. Daily use subjects a sharpener to high wear and tear, while weekly use results in moderate wear. Monthly use causes low wear and tear. Overuse can rapidly degrade the sharpening material, shortening the tool’s useful life.

Replacement Parts Availability for Repair

Even the most durable sharpeners may eventually require new components. Manufacturers who offer readily available replacement parts enhance a sharpener’s longevity. Users can replace worn abrasive belts, rods, or stones, extending the tool’s life without purchasing an entirely new unit. This availability represents a cost-effective and sustainable approach to knife maintenance.

Cleaning Requirements for Your Knife Sharpener

Proper cleaning ensures optimal performance and hygiene for any sharpening tool. Different types of sharpeners have specific cleaning needs.

Ease of Maintenance for Hygiene

Maintaining a clean sharpener prevents the buildup of metal particles and debris, which can hinder its effectiveness. For sharpening stones, users should rinse the stone under running water after each sharpening session. They must scrub away any remaining debris to keep the surface clear. Leaving the stone to air-dry completely prevents moisture-related issues. For stubborn debris, a mild dish soap or specialized stone cleaner can effectively remove grime. Users should periodically flatten the stone using a lapping plate or flattening stone. This addresses unevenness from repeated use, ensuring a consistent sharpening surface. Water stones require proper soaking before each use. This prevents clogging and enhances their effectiveness.

Storage Considerations for Protection

Proper storage protects a sharpener from damage and contamination. Users should store sharpeners in a dry environment to prevent rust or material degradation. Many sharpeners come with protective cases or covers. These accessories shield the abrasive surfaces from dust and accidental impacts. Storing sharpeners correctly ensures they remain in prime condition for future use.

Factor 7: Safety Features of a Knife Sharpener

Safety is paramount when sharpening knives. A sharp blade can cause serious injury if mishandled. Therefore, individuals must prioritize safety features when selecting a Knife Sharpener. These features protect the user and ensure a stable sharpening process.

Hand Protection During Knife Sharpening

Protecting hands from accidental cuts is a primary concern during knife sharpening. Several design elements and user practices contribute to this safety.

Non-Slip Bases for Stability

A stable sharpening platform significantly reduces the risk of accidents. Many sharpeners feature non-slip bases. These bases prevent the tool from sliding on the countertop during use. Securing the knife is crucial during sharpening. A non-slip surface or a stone holder for whetstones enhances safety and prevents slips. This stability allows the user to focus on the sharpening motion without worrying about the sharpener moving unexpectedly.

Finger Guards for Injury Prevention

Finger guards provide a physical barrier between the user’s hand and the blade. These guards are especially important for pull-through and electric sharpeners. They prevent fingers from accidentally slipping into the sharpening slot. Users should always sharpen away from their body. This practice prevents accidents from slips or unexpected blade movements. When a knife handle lacks a ‘D’ guard or similar feature, users must exercise caution. This prevents their hand from sliding up onto the blade, which could cause severe injury to fingers or palm. Keeping hands clear of the sharpening slot is also vital when using electric sharpeners. This prevents accidental contact with the blade. Additionally, wearing cut-resistant gloves significantly reduces the risk of hand injury, especially when using power tools.

Stability During Knife Sharpener Use

Beyond hand protection, the overall stability of the sharpening process is critical. A well-designed sharpener provides control and minimizes movement.

Secure Grips for Control

Ergonomic and secure grips allow users to maintain firm control over the sharpener. A comfortable grip reduces hand fatigue and prevents slips. This control is essential for consistent sharpening angles and safe operation. Users can guide the knife more precisely when they have a secure hold on the sharpening tool.

Weight and Balance for Steady Operation

The weight and balance of a Knife Sharpener also contribute to its stability. A heavier sharpener often feels more planted on the work surface. This reduces the likelihood of it shifting during use. Good balance ensures the sharpener does not tip over easily. These characteristics allow for steady operation, making the sharpening process safer and more effective for the user.

Factor 8: Versatility of Your Knife Sharpener

The ideal Knife Sharpener often extends its utility beyond just kitchen knives. Many users seek a tool capable of maintaining a variety of cutting edges around the home or workshop. Considering a sharpener’s versatility ensures maximum value and convenience.

Sharpening Other Tools with Your Knife Sharpener

A truly versatile sharpener can tackle more than just culinary blades. This capability saves money and space by consolidating sharpening needs into one device.

Scissors Sharpening Capability

Many sharpeners offer dedicated slots or attachments for scissors. This feature allows users to restore the cutting power of household scissors, garden shears, and even pruners. Work Sharp Tools, for example, provides specific solutions for sharpening scissors and pruners. Their Knife & Tool Sharpener can effectively sharpen common tools like scissors, axes, hatchets, mower blades, garden shears, and shovels. It handles most tools with a cutting edge. A verified buyer, Bret E., reported that the sharpener’s design and guide made it easy and satisfying to sharpen knives, shears, scissors, axe heads, picks, and pocket knives. He also mentioned using it to sharpen “ailing tools” at other people’s houses, highlighting its effectiveness for a range of tools.

Outdoor Knives and Specialty Blades

Beyond kitchen implements, a versatile sharpener can maintain outdoor knives, hunting knives, and other specialty blades. This includes tools like axes and hatchets, which often require robust sharpening capabilities. The ability to sharpen these diverse tools makes a sharpener an indispensable asset for homeowners and outdoor enthusiasts alike.

Angle Adjustability in a Knife Sharpener

The angle at which a blade is sharpened significantly impacts its performance and durability. Different knives and tasks require specific angles.

Fixed Angle Sharpeners for Simplicity

Fixed-angle sharpeners offer simplicity and ease of use. They come with pre-set sharpening angles, making them ideal for beginners. Users simply pull the blade through the designated slots, and the sharpener maintains a consistent angle. This design ensures a basic, functional edge without requiring advanced technique.

Variable Angle Sharpeners for Customization

Variable angle sharpeners provide greater control and customization. These systems allow users to adjust the sharpening angle to suit different blade types and personal preferences. This feature is particularly beneficial for specialty knives, Asian-style blades, or for those who desire a specific edge geometry. Adjustable angles enable users to achieve optimal sharpness and edge retention for each individual knife.

Factor 9: Space and Storage for Your Knife Sharpener

The physical footprint of a Knife Sharpener often influences a purchasing decision. Kitchens and workshops vary in size. Users must consider how a sharpener fits into their available space. This factor ensures convenience and accessibility.

Compact Knife Sharpeners

Compact sharpeners offer practical solutions for limited spaces. Their small size makes them easy to store and transport. These tools cater to individuals with minimal counter or drawer space.

Drawer Storage Solutions

Many compact sharpeners fit neatly into kitchen drawers. This keeps them out of sight and protects them from dust or damage. The Alpha Tek Pocket Knife Sharpener, for example, features a design allowing it to hang in a pocket or backpack. This ensures constant availability. The Wusthof 2-Stage Pocket Knife Sharpener is another portable, pocket-sized option. It includes a keychain for easy carrying. The Sharpal Knife Sharpener & Survival Tool is durable and compact. Users can easily carry it in a gear bag for camping and fishing trips. The Lansky QuadSharp Knife Sharpener is small and lightweight. It is compact enough for camping, hiking, and fishing. The Smith Jiffy-Pro Handheld Sharpener is simple and versatile. It is ideal for home, field, or camping use. Users can attach it to a pack or belt. The Spyderco Tri-Angle Sharpmaker is an excellent all-around sharpening system. It is highly portable. Its entire setup fits snugly into a plastic base and lid. This creates a very compact kit for easy storage and transport.

Minimal Counter Space Requirements

Some compact sharpeners, even electric models, require minimal counter space. The Chef’sChoice Trizor XV Professional Electric Knife Sharpener has a compact design. This makes it suitable for small spaces despite its electric nature. The KitchenIQ Edge Grip 2-Stage Knife Sharpener is very portable and compact. Its small size and low price appeal to those with limited kitchen space. These options provide functionality without cluttering work surfaces.

Larger Knife Sharpening Systems

Larger sharpening systems offer advanced features and capabilities. However, they demand more significant space considerations. Users must plan for their storage and accessibility.

Dedicated Storage Area Needs

Comprehensive sharpening systems, such as belt sharpeners or elaborate guided systems, often require a dedicated storage area. These tools do not fit into standard drawers. Users might need a shelf in a pantry, a cabinet, or a designated spot in a workshop. Proper storage protects the equipment and keeps it organized.

Countertop Presence and Accessibility

Some larger sharpeners, especially electric models, might remain on the countertop for easy access. Their size and weight make frequent moving impractical. Users should assess if their kitchen or workspace can accommodate a permanent fixture. This ensures the sharpener is always ready for use.

Factor 10: Brand Reputation and Reviews for a Knife Sharpener

Selecting a Knife Sharpener involves more than just features. The manufacturer’s reputation and feedback from other users offer valuable insights. A reputable brand often signifies quality, reliability, and effective performance. User reviews provide real-world experiences, highlighting strengths and potential drawbacks.

Trusted Manufacturers of Knife Sharpeners

Established brands often lead the market due to their consistent product quality and innovation. Consumers can generally trust these manufacturers for durable and effective sharpening solutions.

Industry Leaders in Sharpening Technology

Several companies stand out as industry leaders. They consistently produce high-quality sharpening tools. Zwilling J.A. Henckels, known for its knives, offers handheld sharpeners with ergonomic designs and non-slip grips. These sharpeners cater to both Eastern and Western knife styles. Chef’sChoice is another prominent name, with models like the 1520 AngleSelect Professional Electric Knife Sharpener often recognized as a top electric option. For those preferring traditional methods, King Whetstone Starter Sets receive strong recommendations. Cangshan also provides comprehensive knife care and sharpening kits, including their SHARK Series 4-Stage Knife Sharpener, noted for its design.

Specialized Sharpening Brands for Expertise

Some manufacturers focus on specific sharpening niches, demonstrating deep expertise in their fields.

| Manufacturer | Specialization/Key Feature |

|---|---|

| Kalamazoo | Industrial-grade sharpening solutions, heavy-duty belt grinders, robust and reliable equipment. |

| Magna-Matic | Leader in lawn and garden tool sharpeners, focuses on durability and ease of use. |

| Nebraska Blades | Specializes in clipper blade sharpeners, ensures precision and longevity for grooming tools. |

| Tru Hone | Commercial knife sharpeners trusted by food industry professionals for speed and precision. |

| Edge Pro | Precision and versatility in sharpening systems, accommodates a wide variety of blades. |

| Nano-Hone | Unique line of sharpening products with precision-engineered diamond resin abrasives for an unparalleled sharpening experience. |

KITCHELLENCE offers a versatile 4-in-1 handheld sharpener. It features diamond, tungsten steel, and ceramic rods for various sharpening stages. Tumbler The Original Rolling Knife Sharpener also receives recommendations for its unique approach.

User Feedback on Knife Sharpeners

Real-world user experiences offer practical perspectives on a sharpener’s performance. These insights complement manufacturer claims.

Online Reviews for Real-World Experiences

Online reviews provide valuable feedback from everyday users. The Chef’s Choice Trizor XV consistently receives praise as a “no-fuss sharpener.” Users report it delivers consistently sharp edges quickly, often achieving “tendon-cutting” sharpness within five minutes. They appreciate its robust build and clean design. The Work Sharp Ken Onion model is highly regarded for its flexibility. It accommodates various angles and blade types, producing “mirror-like edges” on diverse tools. While it has a learning curve, its versatility is a significant advantage. For budget-conscious home cooks, the Cubikook CS-T01 Manual Sharpener offers a safe and effective solution. It balances sharpness with edge integrity and features a stable base. The Presto EverSharp is another budget-friendly option. It quickly sharpens knives to a high level, producing even bevels with durable stones.

Expert Recommendations for Informed Choices

Expert reviews often provide detailed analyses and comparisons. These recommendations help consumers make informed decisions. Experts evaluate sharpeners based on performance, durability, ease of use, and value. They often test products rigorously, offering insights into which sharpeners excel for specific needs or skill levels.

Quick Comparison Guide for Your Next Knife Sharpener

Choosing the right Knife Sharpener simplifies kitchen tasks. This guide offers recommendations based on user skill and specific knife types. It helps individuals make an informed decision.

Best Knife Sharpener for Beginners

Recommended Types for Easy Learning

Beginners benefit from sharpeners offering simplicity and consistent results. The Work Sharp Precision Adjust stands out as an excellent choice. It is affordable and upgradeable. This system works on a wide variety of knives. Its clamp system ensures consistent angles. It includes 320 and 600 grit diamond stones, plus fine ceramic. The Spyderco Tri-Angle Sharpmaker also provides an accessible option. It features 15–20 degree angle guides.

Key Features for Simplicity

Simplicity is key for beginners. Sharpeners with fixed-angle guides or clamp systems minimize the learning curve. They help users achieve a functional edge without extensive practice. The Work Sharp Precision Adjust, for example, effectively restores neglected knives. It offers room for growth with an upgrade kit. The Spyderco Tri-Angle Sharpmaker uses high alumina ceramic stones. It includes medium-grit stones and a scissor setting. Its plastic base and case make it easy to store and transport.

Best Knife Sharpener for Enthusiasts

Recommended Types for Advanced Control

Enthusiasts often seek advanced control and precision. The Wicked Edge Gen 4 is a top recommendation for this group. It features an ultra-secure clamp system. It includes excellent stones (100/200, 400/600, 800/1000 grit diamond). This system can sharpen extremely long blades. It offers angle guides from 12–28 degrees. This level of control allows for highly refined edges.

Key Features for Precision

Precision tools offer customizable angles and superior abrasive materials. The Wicked Edge Gen 4, while having a high price tag and a significant learning curve, delivers exceptional results. It allows users to achieve razor-sharp edges. Its robust construction and comprehensive stone selection cater to detailed sharpening needs.

Best Knife Sharpener for Specific Knife Types

Serrated Knife Solutions

Sharpening serrated knives requires specialized tools. Standard sharpeners often damage their unique edge. The Spyderco Tri-Angle Sharpmaker offers a dedicated scissor setting. This feature can also address serrated edges effectively. Users align the serrations with the ceramic rods for proper maintenance.

Ceramic Knife Solutions

Ceramic knives are extremely hard. They require diamond abrasives for effective sharpening. Specialized sharpeners designed for ceramic blades are necessary. These tools feature diamond stones or belts. They can handle the hardness of ceramic without damaging the blade.

A sharp knife remains essential for kitchen safety, efficiency, and enjoyment. This guide summarized key factors for selecting the ideal tool. These factors include knife types, skill level, and budget. Readers should invest in a Knife Sharpener that perfectly matches their specific needs and knife collection. This ensures optimal culinary experiences.

FAQ

What is the difference between honing and sharpening a knife?

Honing realigns a knife’s microscopic edge. It pushes the edge back into place without removing significant metal. Sharpening removes metal from the blade. It creates a new, sharper edge. Honing maintains sharpness. Sharpening restores it.

How often should one sharpen kitchen knives?

Sharpening frequency depends on usage. Professional chefs may sharpen weekly. Home cooks might sharpen every few months. Honing should occur more frequently, perhaps before each use. A dull knife requires sharpening.

Can a regular knife sharpener sharpen serrated knives?

Most regular sharpeners cannot sharpen serrated knives. Serrated blades require specialized tools. These tools sharpen each individual serration. Using a standard sharpener on a serrated blade can damage the knife.

Are electric knife sharpeners superior to manual ones?

Electric sharpeners offer speed and convenience. They require less skill. Manual sharpeners, like whetstones, provide more control. They allow for precise angles and finer edges. The best choice depends on skill level and desired results.

What grit whetstone should a beginner use?

Beginners often start with a combination whetstone. A common choice is a 1000/3000 or 1000/6000 grit stone. The 1000 grit side handles general sharpening. The finer grit side refines the edge. This combination provides a good starting point.

Can a knife sharpener damage a knife’s blade?

Improper use of a sharpener can damage a knife. Aggressive sharpening or incorrect angles remove too much metal. This shortens the blade’s lifespan. Following manufacturer instructions and practicing proper technique prevents damage.

How does one clean a knife sharpener?

Cleaning methods vary by sharpener type. Whetstones require rinsing with water after use. Electric sharpeners may need brushing to remove metal dust. Always consult the manufacturer’s instructions for specific cleaning guidelines. Proper cleaning ensures longevity.